How Granite is Made?

Quarrying

Because of the structure of granite, it is never quarried by blasting because this may shatter the granite. Two methods are generally used, Drilling and Jet Piercing. They are used to cut the granite out of the quarry.

In Drilling, vertical holes are drilled about one inch apart to the desired depth (up to 20 feet), and the granite remaining between the holes is later removed by secondary drilling.

In Jet Piercing, a high-velocity 4,000 degree flame like a blow torch is directed at the granite to be removed, causing a continuous flaking action. As the flame nozzle is moved back and forth, a deep channel is created in the granite. Granite is much like wood because it has a grain. In one direction granite can be split, but in the other direction it must be cut.

Sawing

Most granite blocks taken from the quarries are cut into slabs of varying widths by modern circular saws with industrial diamond tips.

Polishing

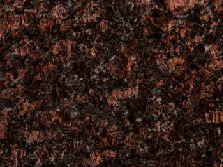

Slabs of granite are polished by special machines that use either large metal discs or abrasive bricks made from silicon carbide. The polishing process produces a sparkling gloss and a finish as smooth as glass.

Epoxying

Epoxy resin may be applied in order to give it a bright and brittle look. Since Granite is a porous mineral, it may contain tiny holes which gets filled by this process.

Finished Granite

A finished granite slab can come in different sizes. Commonly available width is 2’, 2.25’, 2.5’ and 3’ while the length can go upto 10’. The finished granite can be used on any tops, example, table-top, kitchen-tops, Staircase, Flooring, Lift elevation etc.